Colour sorters are machine that are used on the production lines in bulk material processing. They separate items by colours, detecting the colours of things that pass before them, and using pneumatic ejectors to divert items whose colours do not fall within the acceptable range from the rest.

What can a colour sorter do?

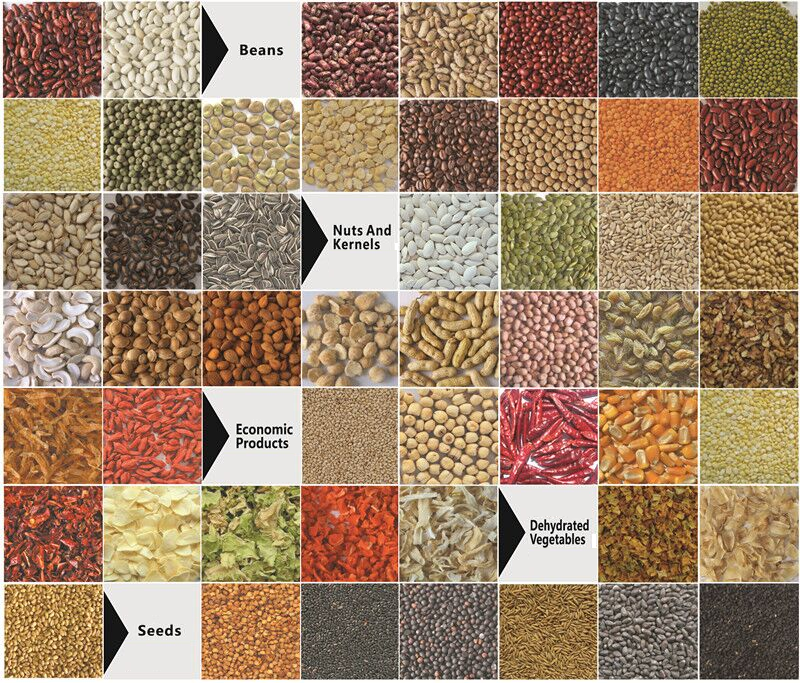

A colour sorter can be used in lots of industries like:

- Grain industry: To remove dockages, defect seeds, weed seeds, broken seeds and etc. Typical usages:

- Clean Fusarium grains. Since Fusarium is poisonous the grains would be downgraded and in some cases have no value at all.

- Remove Canola from yellow mustard.

- Remove brown flax from yellow flax.

- Remove wild oats from oats.

- Improve of grade of pulses like green peas, green lentils and etc.

- Food industry: improve the quality of coffee, tea, nuts…

- Mining industry: pick out the impurities of ore, minerals, stone and sand products

- Recycling industry: separate mixed-colour plastic flakes or granules

How does a colour sorter work?

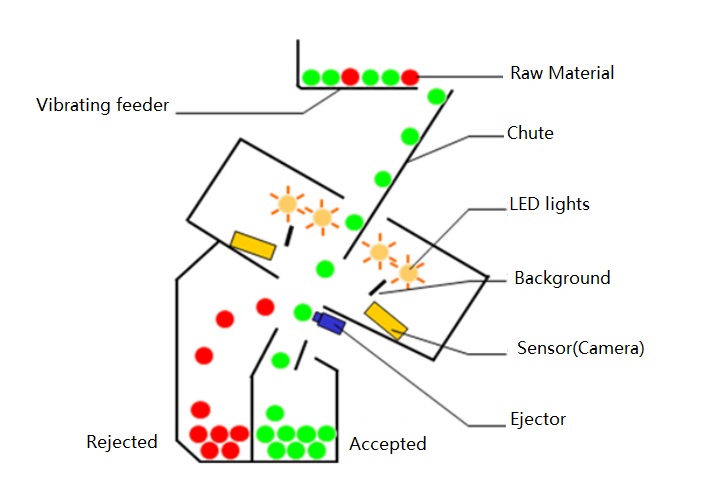

This is the colour sorter working principle.

The raw materials (grains) come into the hopper at top of the colour sorter. Then they go into the vibrating feeder. The feeders spread and level grains to a evenly distributed flow.

The grain flow go down along the chutes. Two sensors ( camera) are installed at both front and back sides of the scanning area ( right at the bottom end of the chute). The sensors capture the images of the grain flow continuously. The digital processor receives the images from the sensors and analyzes in real time.

If the processor decides there’re materials meeting some standards, a strong air flow pulse from the ejector blow it out of the flow. The air flow is generated by opening the valves very shortly, which is controlled by a central unit.

What do you need to know before buying a colour sorter?

- What can a colour sorter do for you? Please see the above question.

- Colour sorter is not a single machine, it’s a system.

- In most of cases, you need pre-clean the grains. Colour sorter won’t work or the speed is very low if the grains are dirty.

- Air compressor is necessary. The ejectors are pneumatic and need a lot of air when working at full speed. For a 4-chute colour sorter, a 20 horsepower air compressor is a decent choice.

- A grain leg is necessary when the colour sorter is working in recycle mode. Please see below for recycle mode.

- The capacity or speed is not a simple figure. It is a wide range depending on the dockage percentage. E.g. A colour sorter clean 2% wild oats out of oats, running at 200bph. But if the wild oats is 5% then it might run at 100bph or even slower.

- If you know exactly what grain(cereal, flax, peas…) you will deal with then choose the model designed for it. You can get perfect result. Otherwise a general purpose model also works, might be a bit slower or less so accurate.

- It works good only in reactively warm temperature, usually above zero. So put it in an insulated room or build one.

- A good dust collector is very helpful. Colour sorters have dust collector pipe adaptors. But it doesn’t have a built in dust collector. When dust build up on the glass of the scanning window, the performance will be getting worse.

- Three phase power is required. Colour sorter itself can use single phase but a big air compressor needs three phase power.

- You might need a lot of clearance to install it. The colour sorter is 8-10 ft high. It needs at least 6ft for spouting under it (Drag augers can be installed to eliminate this 6ft requirement). Usually an overhead grain hopper is installed on top of it.

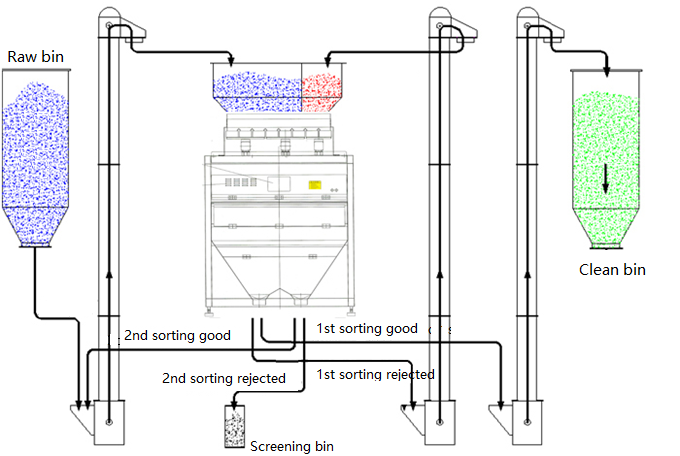

Recycle mode of colour sorter

To get a better colour sorting result, we can use recycle mode:

- Raw grains go to 1st hopper/chute group (blue).

- Accepted grains go to clean bin, rejected go to 2nd hopper/chute group(red).

- Grains in 2nd group are divided into:

- accepted-go back to 1st group

- rejected-go to screening bin

With this mode we can get a good balance between Accuracy and Carryover Rate(Good: Bad). The cost is lower speed.

We provide colour sorter

- High speed HD camera, capture high resolution pictures real time

- Advanced software recognition technology

- Full color LED light

- High reliability ejector valve

- Intelligent system, easy to use

- Internet ready, remote control online

- Infra-red (optional)

- Wide capacity ranges, chute number: 1 – 10

- Air compressor ( optional)

- We sell color sorter parts: LED light, ejector, filters and etc.

We have both new and used colour sorter for sale.